I’d bet that there is more than one past conversation that went like this. “What’s he do for a living?”

“He’s a mechanic.”

“Oh, nice! Cars? Trucks?”

“Nope.”

“Aircraft? Heavy equipment?”

“Nope, he’s a mechanic in a bicycle shop.”

“Oh…..”

What’s the matter? You thought he was something “greater”? One of those “important” mechanics? Sorry to burst your bubble.

Bicycle shop mechanic. The world inside of the doors of a bike shop such as the Brantford Cyclepath is a strange one, familiar to some and yet alien to others. It’s a place where you have to walk the talk. A place where the ability to think on the fly and problem solve creatively become valuable traits.

In bike shops of yesteryear the repair menu wasn’t too deep. Keep wheels rolling true, make sure that the various nuts and bolts were properly tightened (we don’t need no steenkin’ torque wrench!), and repair punctured tires. More advanced shops may have gotten into hub and bottom bracket maintenance. There wasn’t really much to do in the way of a “tune up”. Fairly straight forward stuff.

By the 1970’s your typical shop mechanic was dealing with cable actuated caliper brakes and multiple geared derailleur systems on a daily basis. Since the drive train was still friction shifted and not yet indexed, adjusting gears was still an easy thing to do. However, for the average ten speed owner, it was all starting to become a mystery, and the local bike mechanics were starting to gain notoriety. Add in all of the other jobs such as tire repair, component replacement, wheel maintenance, hub and headset and bottom bracket servicing (yes, you did that back in those days… none of this throw away stuff) and the average day in a bike shop became just a bit more busy.

By the time the mid 1980’s rolled around we were adding plenty of dirt riding in the form of BMX biking and early mountain biking. It’s only natural that if you ride a bicycle off road with a heavy hand, you’re going to break parts. It’s safe to say that before this era, breaking a bicycle wasn’t too common an occurrence. Frame failures used to be a rarity. With the popularity of BMX and MTB riding, the service areas of bike shops everywhere got really busy with mechanics replacing broken parts. When Paul Turner invented the RockShox suspension fork in 1989, you know what happened. Bike shop mechanics had a whole other component to dissect, figure out and memorise. In the same year, Shimano introduced Rapidfire index shifting for mountain bikes. Complex braking systems such as the roller cam and delta brake were born during this time. This was the beginning of the end of simplicity for the shop service department.

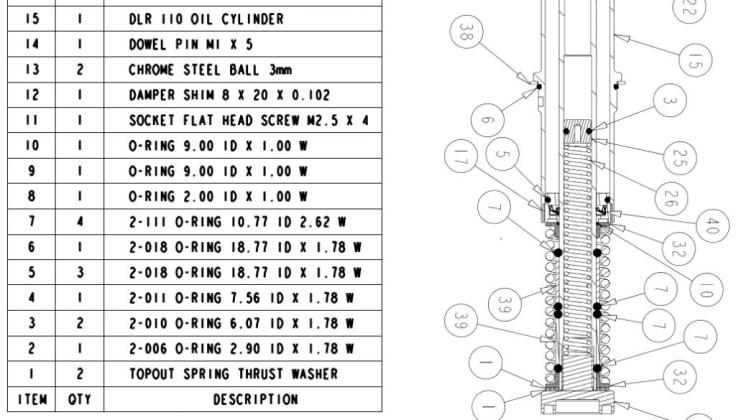

The 1990’s blew everything wide open. In 1990 Shimano introduced the road version of index shifting, the STI lever system. Mountain bikes continued to evolve, bringing rear suspension into the mix. Early hydraulic disc brakes arrived on the scene. There was plenty of component innovation all across the board. Bicycle mechanics were no longer faced with a simple day of replacing inner tubes and adjusting the limit screws of derailleurs. They were becoming familiar with complex hydraulic systems and air and oil damping systems. Two more feathers to add to a busy cap.

Welcome to the new millennia and beyond! As the saying goes “you’ve come a long way baby!” Bike mechanic? Yeah, right. How about Service Technician? These days, the title is far more appropriate for the guys and gals that spin wrenches in your local bike shop. The required knowledge base in order to “fix bikes” at a bicycle shop is now staggering. It isn’t lessening any time soon, either. Yearly advances in technology require both hands-on and online tech classes to be attended. We’ve now added fat bike technology (try figuring out how to build fat wheels from scratch), carbon frames and components that require an experienced touch, electronic shifting with servos, e-bike technology, many new bottom bracket standards, advanced suspension systems, disc brake systems with unique methods of working on each one, the job list goes on and on.

In the life of a bicycle shop mechanic, hydraulic brake bleeds are now a daily occurrence. A few short years ago, they were a rarity with only the head mechanic needing to know how to perform one. Ditto with suspension servicing. Bottom bracket replacement is now almost a mundane repair, rather than a major one. The ability to remember and recall a large mental list of component compatibility is a vital skill. A working knowledge of all systems old and modern is essential. That 1978 Pinarello with Campagnolo Super Record requires the same respect and attention as the latest super bike. Modern bicycles are incredibly advanced machines, requiring more and more time to work on them. Let’s not forget that the stream of basic repairs to the more simple bikes has not decreased due to the rise in cycling’s popularity. Add in the new consumer mantra of wanting it yesterday and it’s no wonder that the face of your favorite shop mechanic can appear weary during the height of the season!

Bicycle mechanics are the unsung heroes of the industry. The racers seem to get all of the attention, but where would they be without their tech support? Average cyclists are now able to purchase very advanced bicycles and the local shop mechanic is the partner that will keep the bike performing well, year after year.

“What’s he do for a living?”

“He’s a mechanic.”

“Oh, nice! Cars? Trucks?”

“Nope.”

“Aircraft? Heavy equipment?”

“Nope, he’s a mechanic in a bicycle shop.”

“Really? Wow! That’s awesome!”

#brantfordcyclepath

#bicyclemechanic

#bicyclerepair

Recent Comments